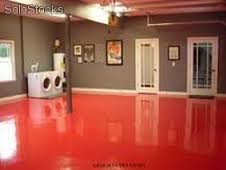

On my last article on epoxy floor finish we ended by preparing the floor before an epoxy was applied. This week we continue by first selecting the type of epoxy to apply. Epoxy floor paints are tough resins that come in two separate parts that you mix together just before you apply them. You can divide them roughly into three types: 100 percent solids, solvent based and water based.

The 100 percent solid type is almost pure epoxy; it doesn't contain solvents that evaporate. These products are expensive and difficult to handle because they harden so rapidly.

They're best left to the professionals; I normally specify the solvent-based epoxies typically made up from 40 to 60 percent solids epoxy.

Precautionary measures.

They penetrate and adhere well the sub-base and are the choice of most users. They are often available in a wide range of colours, which is one reason we chose this type for our projects. However they do have some drawbacks. The solvents in it are powerful and potentially hazardous; you MUST use a good mask (a 3M 5000 series respirator with an organic vapour/acid gas filter, or the equivalent in another brand). The mask must fit tightly to your face so you don't breathe any of the fumes. In addition, you must ventilate the space well and keep other people away from the odours.

Solvent-based epoxies may be harder to find. Some paint specialty stores may have them but otherwise you'll have to go to an industrial supplier.

The water-based epoxies also have two parts that you mix just before application. They also typically contain 40 to 60 percent solids. The benefit of this type of epoxy is that there do not have hazardous solvent fumes. Whether you're working with solvent- or water-based epoxy, I do recommend that you apply two coats to get enough build for long-term wear and durability. Typically, an epoxy with a higher solid content will give a larger thickness. And, in general, prices tend to reflect the amount of epoxy in the mix the more epoxy, the larger the thickness, you guessed it, the higher the price.

Check the cans for coverage to make sure you buy enough.

Be careful.

Wear appropriate gloves, eyes and lung protection and rubber boots, always use according to the product labels. Turn off any gas appliances located in the house. And take precautions to keep children and pets away from the building and nearby spaces.

Fill in the cracks!!

First thing, after the floor has dried overnight, fill in any large cracks and larger holes or damage areas, with epoxy crack filler. Use a plastic putty knife to scrape the surface level and smooth. Let this dry (check label directions) before you begin painting your first coat of epoxy.

First coat of epoxy

Mix the two epoxy components for five minutes using a drill and stirring pole. Then pour the entire contents into a second bucket and repeat the power mix to ensure complete blending of the entire mixture.

Mix the correct amount of epoxy to cover the square footage of your garage floor according to label directions. It's critical that you allow the mixed product to standundisturbed for the specified time on the label before applying it. You also must apply the entire batch you mixed up before the specified time expires.

While waiting for the crack filler to cure use a high-quality natural-bristle paint brush and cut in the floor edges. Also, tape the area directly underneath the entrance door with masking or duct tape, allowing you to shut the door overnight. This is intended to keep out dust, dirt, until the floor is dry. And put a “Do Not Enter” sign along with tape across the doorway leading to the house just in case.

Coating the floor

If you move at a steady pace, you could finish your average home in about four hours. Remember not to paint yourself into a corner! The solvent doors are powerful. Be sure to wear a mask at all times and keep the house door open at least an hour after coating.

Second coat

Let the first coat dry according to label directions. If you don't want a glossy floor it's slippery when wet, add a non-skid floor coating additive into the epoxy and stir well to disperse the granules evenly.

Let the first coat dry overnight, for a minimum of 16 hours (or according to label directions, since epoxy products vary).

Wait another 16 hours (check label directions) after finishing before allowing foot traffic. A full cure for the floor takes approximately one month.

Write a comment